Industrial Equipment for Repair and Refurbishment (Cladding & 3D Printing)

- KUKA Germany Multi-Axis Robotic Systems

Parto Pushesh Apadana Company, in collaboration with KUKA Robotics from Germany, has undertaken the design and construction of a six-axis robot tailored for laser cladding operations. In this context, Parto Pushesh Apadana Company provides optimized and customized solutions for programming and automation projects. The services include the sale and support of specialized robot software, process automation, and project management.

- Six-Axis Robot Arm:

- Repeatability: 0.04 mm

- Arm movement up to a 2-meter radius

- Intelligent and fast, without vibration or oscillation of the head

- Connection to the most advanced KUKA controller

2. Two-Axis Positioner

- Unlimited rotational movement of the positioner.

- Synchronous with the six-axis robot arm.

- Capability to add a spindle and linear tracker as the ninth axis.

- Specialized Software for Laser Cladding and Additive Manufacturing of Metal Parts

- Main Controller Siemens Germany

- Industrial Ethernet Communication Network

- Fully Automatic Process Control

- Closed-Loop Control Mode

- Online Process Simulation

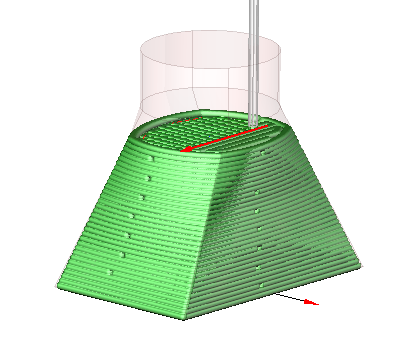

- Laser Cladding and Additive Manufacturing Software

- Direct Conversion of CAD Files to Robot Commands

- Simulation of the Molten Pool in the Process

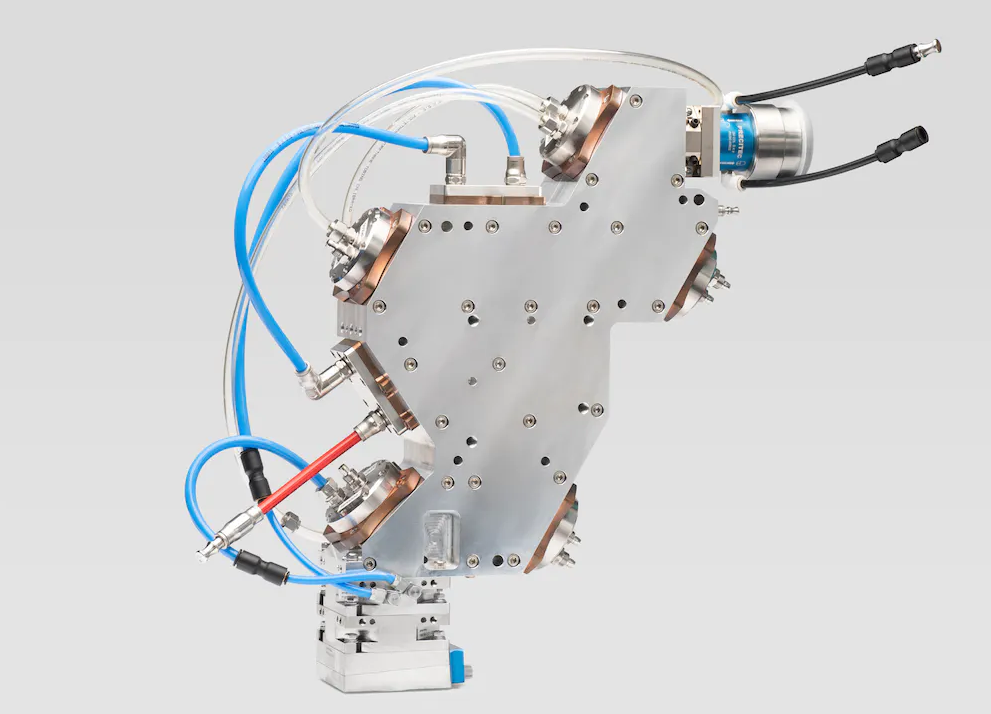

- Optical Heads and Specialized Nozzles for Laser Cladding – European Brand

1. Laser Cladding Head for Moving Inside Components and Equipment with Deep Cavities

- Capable of Cladding holes and cavities with diameters ranging from 38 to 100 millimeters.

- Adjustable head length depending on the length of the component.

- Capable of cladding with various metallic powders and wires.

- Option to equip the head with an industrial camera for process visualization.

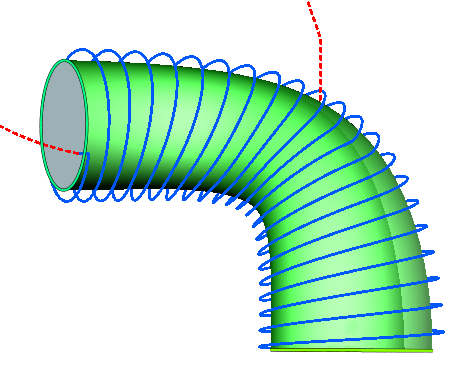

2. Laser Cladding Head for Moving Inside Pipes and Tanks

- Capable of Cladding under harsh industrial conditions and multi-shift operations.

- Compatible with various standard lasers.

- Capable of cladding with different metallic powders.

- Option to equip the head with an industrial camera and temperature sensor.

- Capability to perform laser hardening processes.

3.Wide-Width Laser Cladding Head

- Capable of creating rectangular Cladding with a width of 6 to 30 millimeters.

- Compatible with high-power fiber lasers.

- Significantly reduced execution time.

- Option to equip the head with an industrial camera and temperature sensor (closed-loop process monitoring and control).

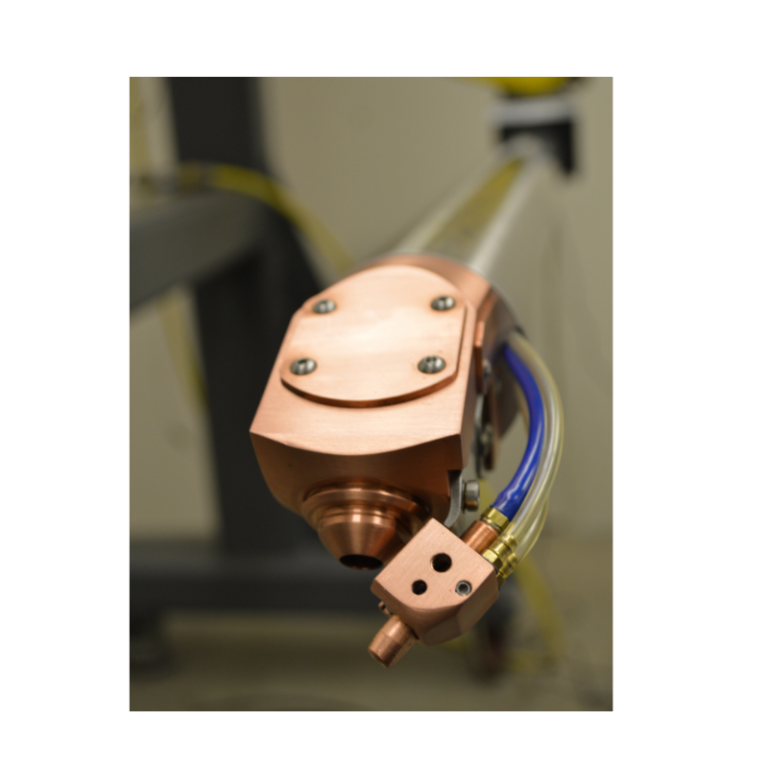

4. Laser Cladding Head with Fine Cladding (Coaxial Nozzle)

- Capable of operating at angles other than 90 degrees.

- Adjustable laser spot size between 2, 4, 5, 6, and 8 millimeters, depending on the optical configuration of the head and the inner diameter of the fiber.

- Compatible with high-power fiber lasers.

- Suitable for three-dimensional additive manufacturing.

- Option to equip the head with an industrial camera and temperature sensor (closed-loop process monitoring and control).

5. Multi-Purpose Laser Cladding Head

- Automatic switching between rectangular and circular laser spots.

- Compatible with various nozzles such as three-way, four-way, and double nozzles, etc.

- Adjustable collimator lens.

- Option to equip the head with an industrial camera and temperature sensor (closed-loop process monitoring and control).

6. Types of Hardening and Additive Manufacturing Nozzles

- Laser Source

- Fiber Laser

- Dual Operation Modes: Continuous Wave and Pulsed (Multi-Function).

- High-Power Output: With capability for power scaling to higher levels.

- Adjustable Power: Ability to change laser power during programming.

- Powder Feeder

- Dual Compartments: Equipped with two separate chambers for handling different types of powders or mixing.

- Volumetric Design and Construction: Built on the principle of volumetric powder feeding to ensure accurate delivery.

- Adjustable Disk Rotation (RPM) and Material Weight (gr/min): Allows precise control over powder flow based on disk speed and material weight.

- High Accuracy and Repeatability: Ensures consistent powder feeding performance for reliable Cladding results.

- Capability for Composite and Mixed Powders: Can produce powders with specified compositions and percentages.

- Pre-heating Capability: Capable of pre-heating powder up to 100°C to enhance powder flow and performance.

- Adjustable Powder Flow During Operation: Enables real-time adjustment of powder feed rate during the Cladding process.